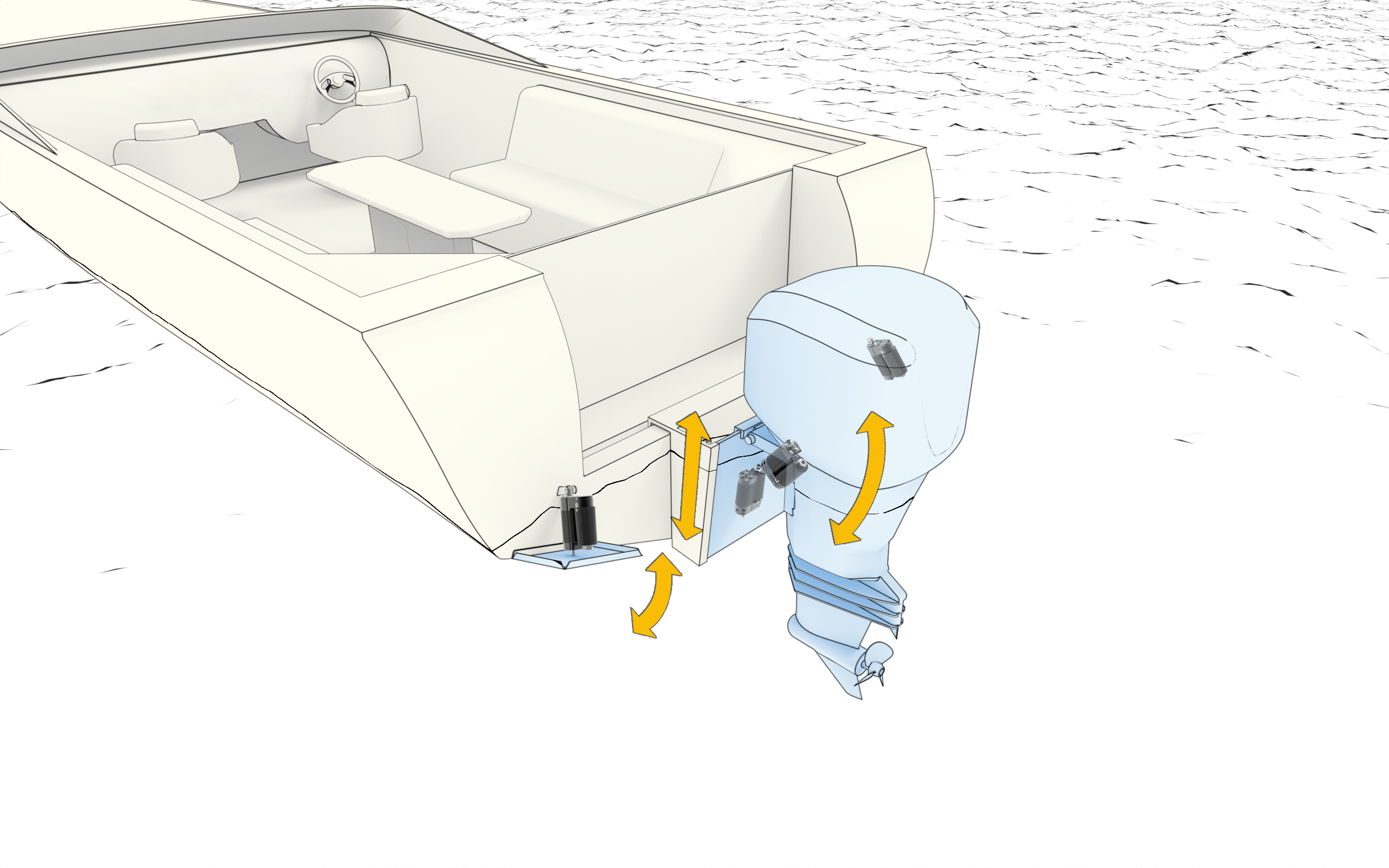

DOWNERS GROVE, IL – Thomson Industries, Inc., a leading manufacturer of linear motion control solutions and brand of Regal Rexnord Corporation, has introduced key enhancements to its H-Track electro-hydraulic actuator, making it more resilient in harsh and high-moisture environments. The latest version features marine-grade 316 stainless steel components for improved corrosion resistance and a sealed motor housing that enables underwater operation, expanding its suitability across marine, agricultural, industrial and off-highway applications. A refined design and optimized online selection tool further improve product availability and ease of integration.

“The industries we serve push equipment to its limits, often in environments where exposure to moisture, salt and debris is unavoidable,” said Travis Gilmer, Global Product Manager – Linear Actuators at Thomson Industries. “The H-Track has been a trusted solution for demanding applications and with this latest evolution, we are not just entering the marine sector, we are raising the standard for durability across all rugged applications.”

Designed to withstand harsh environments

H-Track’s robust, self-contained hydraulic system has always provided the power of hydraulics without the need for hoses, external pumps or regular maintenance. The latest enhancements make the actuator more reliable in applications where conventional models may degrade over time. The latest upgrades include:

- Corrosion-resistant construction – All exposed fasteners, adapters and the piston rod are now 316 stainless steel, a material widely used in marine settings for its high resistance to rust and oxidation. Unlike coated steel, which can deteriorate over time when coatings are scratched or worn, this stainless steel provides lasting durability in saltwater, humid and corrosive conditions.

- Certified for long-term exposure – The H-Track has passed a 2000-hour salt spray test, significantly outperforming typical industry standards.

- IP68 dynamic rating for underwater operation – A newly sealed motor housing allows the H-Track to function while fully submerged, expanding its application range to marine automation, offshore equipment and other water-immersed systems.

Smarter design, faster lead times

Thomson has optimized stroke length and load configurations, making the H-Track easier to specify and faster to deliver. While the design has been refined for manufacturability, it remains fully customizable to meet specific application needs.

H-Track continues to serve as a powerful alternative to traditional hydraulic systems, integrating the pump, motor and cylinder into a single, maintenance-free unit. Its compact design eliminates external hoses and reservoirs, providing high power density and shock-load resistance while also simplifying installation.

“Our focus wasn’t just on marine applications—it was on making a more durable, long-lasting actuator for all rugged environments,” added Gilmer. “This upgrade allows customers across industries to get more reliability, less downtime and a streamlined ordering process, making it easier to integrate into their equipment.”

Availability

The H-Track actuator with marine-grade protection is available for immediate order. For more information, visit https://www.thomsonlinear.com/

About Thomson Industries, Inc.

With more than 75 years of achievement in motion control innovation and quality, Thomson is the industry’s premier producer of Linear Actuators, Linear Ball Bushing® Bearings, Profile Rail Linear Guides, 60 Case® LinearRace® Shafting, Ground and Rolled Ball Screws, Lead Screws, Screw Jacks, Linear Units, Robot Transfer Units and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945 and has set the standard ever since with an unsurpassed set of linear motion control solutions serving global aerospace and defense, medical and health, factory automation, food processing, and mobile off-highway markets. Thomson, a brand of U.S.-based Regal Rexnord Corporation, has facilities in North America, Europe and Asia with more than 2000 distributor locations around the world.

For more information Thomson Industries, Inc., 2400 Curtiss Street, Downers Grove, IL 60515; 1-540-633-3549; 1- 540-633-0294 (fax); Thomson@regalrexnord.com; www.thomsonlinear.com.

About Regal Rexnord Regal

Rexnord’s 30,000 associates around the world help create a better tomorrow by providing sustainable solutions that power, transmit and control motion. The Company’s electric motors and air moving subsystems provide the power to create motion. A portfolio of highly engineered power transmission components and subsystems efficiently transmits motion to power industrial applications.

The Company’s automation offering, comprised of controllers, drives, precision motors, and actuators, controls motion in applications ranging from factory automation to precision tools used in surgical applications. The Company’s end markets benefit from meaningful secular demand tailwinds, and include factory automation, food & beverage, aerospace, medical, data center, warehouse, alternative energy, residential and commercial buildings, general industrial, construction, metals and mining, and agriculture.

Regal Rexnord is comprised of three operating segments: Industrial Powertrain Solutions, Power Efficiency Solutions, and Automation & Motion Control. Regal Rexnord is headquartered in Milwaukee, Wisconsin and has manufacturing, sales and service facilities worldwide. For more information, including a copy of our Sustainability Report, visit www.regalrexnord.com.